In the high-wire act of inventory management, safety stock plays a crucial role. Think of it as your business's safety net—a buffer of extra inventory against stockouts, shifting demand, or supply chain disruptions. Ensure your sales keep humming along even while you wait for new inventory to arrive by maintaining the optimum level of safety stock.

Setting the right level of safety stock is a balancing act. You must weigh the cost of holding additional inventory against the risks of lost sales, frustrated customers, and the higher price of expedited restocking. Read on for essential tips, formulas, and examples that will help you correctly calculate safety stock, ensure optimal inventory levels, and make your operations more resilient.

What is safety stock and why does it matter?

Safety stock is your shield against two big inventory risks: sales variability and supply uncertainty. Sales forecasts can never be entirely accurate and unexpected demand fluctuations will happen. Any supply chain is also susceptible to disruptions like unreliable supplier lead times, geopolitical issues, or shortages of raw materials. By protecting you against these two areas of risk, Effective safety stock management can help protect you against these risks.

- Higher customer satisfaction: Reduce the risk of stockouts, ensuring continuous order fulfilment during demand spikes or supply delays.

- Less emergency restocking: Lower the frequency of expedited restocking and the associated costs.

- Smoother operations: Adequate safety stock levels lead to more stable workflows and schedules, enhancing overall efficiency.

- Stronger supplier relationships: Foster positive ties with suppliers through regular and predictable ordering.

- Better demand forecasting: Gain breathing room to refine demand forecasts without the immediate risk of stockouts.

Tips for effective safety stock management

Determining the ideal safety stock level involves understanding the nuances of your inventory and market. Here are four key factors you should consider.

- Demand variability: Items with unpredictable sales demand need more safety stock than those with steady demand patterns. This is crucial for items with seasonal or trend-based demand.

- Lead time reliability: Items sourced from suppliers with fluctuating lead times require more safety stock to protect against stockouts.

- Customer service levels: High standards for customer satisfaction might mean keeping extra stock to fulfil orders instantly.

- Cots and benefits: Weigh the costs of ordering and holding inventory against the benefits of additional safety stock.

A strategic approach tailored to your unique inventory needs and market dynamics is essential for effectively managing safety stock. This involves identifying the right level of stock to hold and continuously monitoring and adjusting these levels in response to changing demand patterns and supply chain conditions. Here are some recommendations for striking the right balance.

- Conduct ABC analysis to set safety stock levels based on product importance,

- Improve supplier collaboration to negotiate better lead times and more reliable restocking,

- Establish a cross-functional team that regularly meets to review forecasts, inventory levels, supply chain issues, and customer demand,

- Agree the right KPIs to monitor and adjust safety stock,

- Optimise reorder points to maintain balanced inventory levels,

- Focus on refining forecasting techniques to better anticipate demand changes.

Four safety stock formulas you should know

Understanding and applying the safety stock formulas most suited to your business can make all the difference. Whether you're dealing with seasonal fluctuations, supplier reliability issues, or aiming for top-notch customer service, adapting these formulas to your specific needs ensures you maintain optimal inventory levels, reducing the risk of stockouts while avoiding excessive inventory costs.

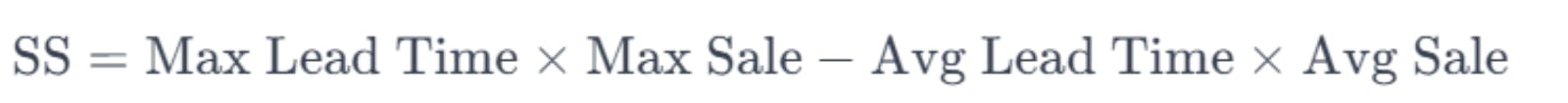

Simple safety stock formula

This formula is a good starting point for calculating safety stock for items that have stable demand throughout the year, such as USB cables. It assumes that what happened in the past will happen again in the future.

Safety stock formula that takes into account demand fluctuations

This formula is useful for items with uncertain demand, such as sunscreen — which will see sales volume change based on the season. It’s useful if your lead times are quite stable or you don't have data about demand patterns.

Safety stock formula that takes into account lead time fluctuations

This formula addresses lead time variability and can be useful if your demand uncertainty is negligible in comparison. For instance, an electronics wholesaler could use this formula for components sourced overseas, where lead times vary due to factors like production schedules or customs delays.

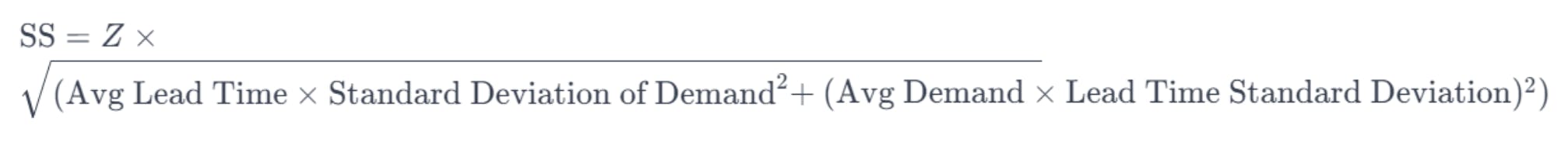

Safety stock formula that takes into account lead time and demand fluctuations

This more advanced safety stock formula accounts for both lead time and demand uncertainty. A fashion wholesaler, facing both seasonal demand changes and variable lead times from different suppliers, could benefit from this approach.

The right safety stock calculation will depend on your specific industry, products, and supply chain. Remember — safety stock is more than just a number. It's a dynamic part of your inventory management strategy, constantly evolving with market trends, supplier reliability, and customer demand.

We can help!

Well-managed safety stock ensures inventory stability, resilience, and cost-effectiveness — enabling you to meet customer orders efficiently, even amidst unforeseen demand and supply chain challenges. Mastering the art and science of safety stock calculations is a crucial step towards optimised inventory management, but it's just part of the larger picture. For a more comprehensive and streamlined approach, consider adopting a solution that simplifies and enhances this process.

Fast to implement, easy-to-use, and highly scalable — our cloud-based inventory management software has everything you need to avoid stockouts on important items and bring your supply chain to the next level. Our ability to generate more precise safety stock calculations will keep you one step ahead in the ever-evolving marketplace. Instead of taking an inaccurate one-size-fits-all approach to safety stock, we monitor each individual product by sales history, confidence factor, and order period. We can also apply five different forecasting models to find the most accurate fit for each item’s future demand and catch all possible trends.

Learn more about how we can help or book a personalised demo.