When we’re struck by the streamlined beauty of a sculpture like Michelangelo’s David, we can’t see the artist’s most crucial choice — what to remove. The same principle applies if you want to sculpt an efficient and optimised inventory. You need to cut away underperforming or redundant items to carve out a portfolio focused on your most profitable and relevant products.

By using SKU rationalisation, you can hone your inventory like a master sculptor — strategically assessing and adjusting the variety of items you offer. By focusing on core SKUs that drive the most revenue, you can avoid a badly proportioned inventory that creates higher storage costs, reduced cash flow, and more complex management.

What is SKU rationalisation and why does it matter?

It isn’t just about reducing numbers; it's about smartly aligning your inventory to your market demands, operational capabilities, and financial goals. By protecting you against overcomplexity that slows down your supply chain and eats into your profits, effective SKU rationalisation brings many benefits.

- Cut costs: Streamlining your product portfolio optimises storage costs and reduces dead stock, driving financial savings and better return on investment.

- Free capital: By reducing excess inventory, SKU rationalisation can improve your cash flow.

- Simplify inventory management: Fewer SKUs translates into more efficient and less time-consuming inventory management, improving profit margins.

- Drive competitiveness: Tailoring your product portfolio to align with customer demands enhances your competitiveness and accelerates your speed to market.

- Enable flexibility: A leaner product range enhances your supply chain's adaptability, allowing faster responses to changing market trends or customer demands.

Tips for effective SKU rationalisation

Streamlining your product portfolio can seem like a complex and daunting task. Sorting your high-performing items from the underachievers isn’t just a one-time exercise, but a continuous strategic process that demands input and buy-in from across your business. If you‘re unsure about where to begin, we recommend focusing on four critical areas that will help ensure your inventory is aligned to both market demands and your business goals.

- Assess your target markets: Tune SKUs to specific customer needs, your business strategy, and market competition. Leverage demand planning and forecasting tools to anticipate future trends and adjust your portfolio accordingly.

- Conduct SKU analysis: Continuously evaluate the performance of each SKU, focusing on storage requirements, demand volatility, and inventory turnover. This ongoing analysis is vital to distinguish between high performers and underachievers.

- Organise your product catalogue: Categorise SKUs into groups such as 'keep', 'remove', or 'review'. This enables more clarity and streamlines decision-making during inventory audits.

- Review the results: Establish a cross-functional team that regularly reviews the effectiveness of your SKU rationalisation. This team should focus on product lifecycle management and make informed decisions about which SKUs to discontinue. Continuous monitoring is vital here, as market trends and customer preferences can change rapidly.

Four SKU rationalisation formulas to know

A range of formulas can help you drive SKU rationalisation and make more informed decisions about what items to focus on or eliminate. These formulas vary in complexity and applicability, so picking the right ones depends on your business's unique strategy and product portfolio.

For functional products with long and stable life cycles, simple criteria like sales volume and profitability are sufficient. For an innovative product mix with shorter life cycles, SKU rationalisation is more complex and you‘ll need a continuous review process in place. It’s also important to monitor several of these metrics — relying on just one can provide a skewed perspective that leads to the wrong decisions.

- Pareto ABC analysis / 80-20 rule: This classic principle suggests categorising SKUs based on their contribution to turnover. It operates on the idea that a small proportion of your products likely generates a majority of your revenue, guiding you to focus on these high-value items.

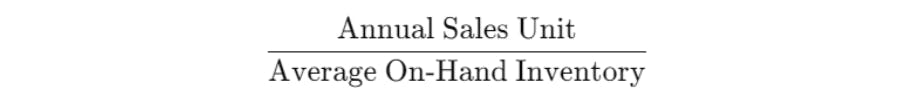

- Sales velocity:

This formula helps identify which items are sold and restocked quickly. By focusing on these in-demand products, you can maintain a dynamic and responsive inventory.

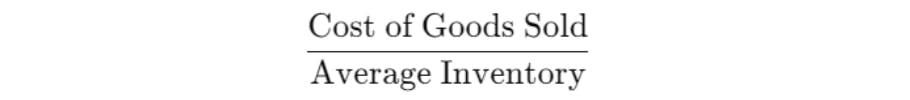

- Inventory turnover:

This metric is crucial for items with expiration dates or fashion-sensitive goods. It helps focus on SKUs that move quickly through the inventory, avoiding overstock and obsolescence.

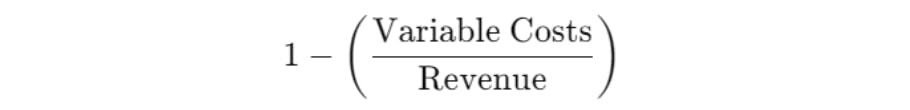

- Profitability analysis:

This formula determines the profitability of each SKU, helping to maximise margins. It’s essential for understanding which products contribute the most to your bottom line.

Overcoming SKU rationalisation challenges

Even the most carefully planned SKU rationalisation strategies can face obstacles. Preparing for these challenges is essential to ensure the success of your inventory optimisation efforts. Let's examine three common hurdles and how to overcome them.

- Inaccurate demand planning and forecasting: Misjudging which products will be in demand can lead to discontinuing the wrong SKUs, resulting in lost sales. Read our recommendations on how to drive more accurate demand planning and forecasting. (LINK TO DP1 BLOG)

- Supplier disruption: Changes to SKU portfolios can create problems with supplier relationships. You can address this by ensuring transparent communication, involving suppliers early, and implementing portfolio changes gradually.

- Resistance to change: Sales and marketing teams often disagree with operations on the need for SKU rationalisation — perhaps because they have established relationships with certain products or fear a loss of variety. To mitigate this, clearly address concerns and communicate benefits, set the right KPIs, and embed a “win-win” mindset early on.

We can help!

With accurate forecasts informing your demand plans, you’ll reduce unnecessary carrying costs, avoid stockouts, and maximise sales. You’ll also have happier customers, improved brand perception, and better supplier relationships.

Fast to implement, easy-to-use and highly scalable, our cloud-based software has everything you need to drive accurate demand planning and forecasting. With cutting-edge tools rolled into one risk-free subscription, it’s the missing link in your business success. With five different forecasting models, we can find the most accurate fit for each item’s future demand and catch all possible trends, while our advanced data visualisation capabilities and reporting dashboard will help you make informed decisions quicker than ever before.

Learn more about how we can help or book a personalised demo.